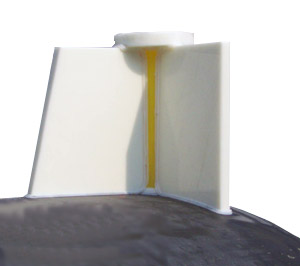

The Pad Flange is the perfect answer to drain any cone bottom tank. Cone bottom tank stands usually allow a standard of 12" for piping clearance. This helps keep the overall height of the tank down, but also makes using large pipes very difficult. Our Pad Flange can be constructed in any applicable size and only projects 1" off of the lowest surface of your tank. The Pad Flange features corrosion resistant thread inserts, a Full raised face design, and a internal/external heavy duty seal. Specifically designed for cone bottom tanks, this fitting is a perfect accessory for any mixing application. |

Super Flanged Nozzles™ fittings and accessories

Eliminates metal and gasket combustion of mechanical fittings. 1" thick flat faced flanges supported flange to tank with ½" thick full plate gussets.

Maximum Strength and Corrosion Resistant Flanged Nozzles - Couplings - Mixing Baffles - Pump Brackets - Piping Support - Ladder Brackets

Welded Flanged Nozzles & Fittings Offer:

• Maximum Strength

• No need for metallic parts or gaskets

• 150# bolt spacing, full faced flanges

• Plate gusseted, tank wall to flange face

• Hand welded with Nitrogen Gas provides a stress-free connection with maximum corrosion resistance

• Welded nozzles offer maximum placement options. Full drains, the very top of the straight side are possible without the need for special Fitting Flats and Universal Fittings.

Plate Gusseted Flanged Nozzles:

Plate Gusseted Flanged Nozzles:

• Standard sizes 1 ½" to 12"

• Standard projection is 6" but (as shown to the left) longer project are also available

FNPT Couplings Full or Half:

• Standard sizes ½" FNPT to 4" FNPT

• Full or Half Couplings available

• Plate Gussets are available for maximum support. Extra thick gussets (as shown to the left) are also available.

• Unlimited locations for placement

This fitting comes in all of our standard sizes (2,3,4,6,8,10,12,16). It can be made black for further UV protection

This fitting comes in all of our standard sizes (2,3,4,6,8,10,12,16). It can be made black for further UV protection , and the face can be made thicker for further stability. It can be located almost anywhere on your HDLPE tank giving you more flexibility in piping.

, and the face can be made thicker for further stability. It can be located almost anywhere on your HDLPE tank giving you more flexibility in piping.